Environmental Management

GRI 3-3

Supported by the guidelines and requirements established by international environmental management standards (ISO14001) and energy efficiency management (ISO 50001), our environmental management values operational efficiency, the optimization of natural resources and a reduction in waste, thus emphasizing the circular economy.

With its reforestation, environmental education and waste reduction initiatives our Cabo de Santo Agostinho (PE) plant follows the principles of Industry 4.0. A pioneer in operations in the region, Aché launched its Environmental Education Program in 2022, which is aimed at teachers, students, and the managers of municipal schools in the Cabo de Santo Agostinho region, which has an impact on more than 1,000 local students with its educational activities.

One of the first results of this initiative was the replanting of 7,500 seedlings of tree species that are native to the Atlantic Forest biome in the Zumbi (port region of Suape). The reforestation project, which started in 2020, was designed to carry out the environmental compensation of 4.47 hectares of the region. As a result it has helped re-establish the balance of the local ecosystem, with recovery of the degraded area, a reduction in the greenhouse effect and a re-balancing of the environment.

Another initiative, also in Pernambuco, is the leasing of pallets with the aim of reducing the cost of purchasing this material and, with it, reducing the environmental impacts caused by the consumption of wood. As a result, the partnership preserves approximately 780 trees per month, with an estimated reduction of 324 tons in CO2 emissions2.

We have also developed a process to ensure the reuse of pallets in non-ideal conditions for internal use in the factory. Since it was implemented, approximately 300 pallets per month have been allocated to Neolog, Aché’s general warehouse in Guarulhos, thus reducing our generation of waste by some ten tons per month.

Energy Management

GRI 3-3 | 302-1 | 302-3 | 302-4 GRI 3-3 | 302-1 | 302-3 | 302-4

We improved our energy management throughout 2022. We ensure the energy efficiency of our Guarulhos plant with ISO 50001 certification.

Stratification of electrical loads showed that air conditioning was the major cause of our high energy consumption, representing 28.4% of the total consumed. Given this scenario, the unit introduced improvement projects in the air conditioning system, which represented a 1.9% reduction in electricity consumption in 2022. In relation to total energy consumed (GJ) in the Company’s five plants, there was a 10% increase relative to the previous year due to the start of Phase II operations (the manufacture of solids) in the Pernambuco unit and expansion of the production area (microdosing) in São Paulo.

Because of the practices and the results obtained in Guarulhos, the Company’s strategy is to extend ISO 50001 certification to other plants.

Atmospheric emissions

GRI 3-3 | 302-1 | 302-3 | 302-4 GRI 3-3 | 302-1 | 302-3 | 302-4

Aché is conscious of the role industries have to play in combating climate change. We devise combined actions that involve improving energy efficiency, adopting lowcarbon technologies, and promoting circularity. To assess the impact of the emissions from our operations, every year we prepare a greenhouse gas (GHG) emissions inventory according to the GHG Protocol methodology. With information from the inventory we set targets and identify key opportunities for reducing our GHG emissions.

Note: Numerical data are in portuguese.

The increase in Scope 2 emissions is related to the increase in total energy consumption. Aiming at reducing emissions, we have structured a mitigation plan, whose targets, percentages, and deadlines will be defined in 2023.

Management of Waste and Reverse Logistics

GRI 3-3 | 306-1 | 306-2 | 306-3 | 306-4 | 306-5

Our production process involves the consumption of different types of raw materials, thereby generating waste from production leftovers, which result in the need to dispose of packaging and medicines. For this reason we have expanded the circular economy concept in the different stages of our operation, thus mitigating the impact of our use and disposal of materials. This practice prioritizes the best use of raw materials, by increasing reuse and recycling waste.

In managing our waste we follow the relevant current environmental legislation and the principles of the Company’s IMS Policy. The initiatives include the storage of hazardous waste with access control; waste packaging with identification; documents and records for controlling traceability to the final destination; adequate transportation with verification of the necessary documentation; and a final disposal process with a certificate, including proof of the destruction of controlled products. To control and monitor these actions we follow the Solid Waste Management Plan and carry out internal and external audits with regulatory agencies.

In one of the actions of the PEO -Operational Excellence Program (see page 58) we analyzed waste that has the potential for inclusion in the circular economy, according to the life cycle perspective criteria of ISO 14001.

A partir dessa análise, estabelecemos parcerias para o reaproveitamento de itens como paletes (já iniciado, saiba mais), caixas plásticas, bombonas de 200L e tarugos (plástico e alumínio), que devem retornar aos fornecedores para serem reutilizados.

For medical waste generated after consumption, we established a Reverse Logistics program in accordance with Federal Decree No. 10,388 of 2020. The following were our partners in implementing this program: Sindusfarma – LogMed Program ; Abihpec – Hand to the Future Program ; and Abiad – Recover Program. The plan for 2023 is to further expand the reverse logistics facility for unused medicines to include those Brazilian unicipalities in which Aché has a presence.

Note: Numerical data are in portuguese.

Packages

We underline our commitment to the whole packaging and product chain, from manufacturing to waste disposal, and emphasize the correct disposal of medicines. We include guidance to consumers on the correct disposal of medicines and packaging in our package inserts, on our institutional website, and via the CAC (Customer Service Center).

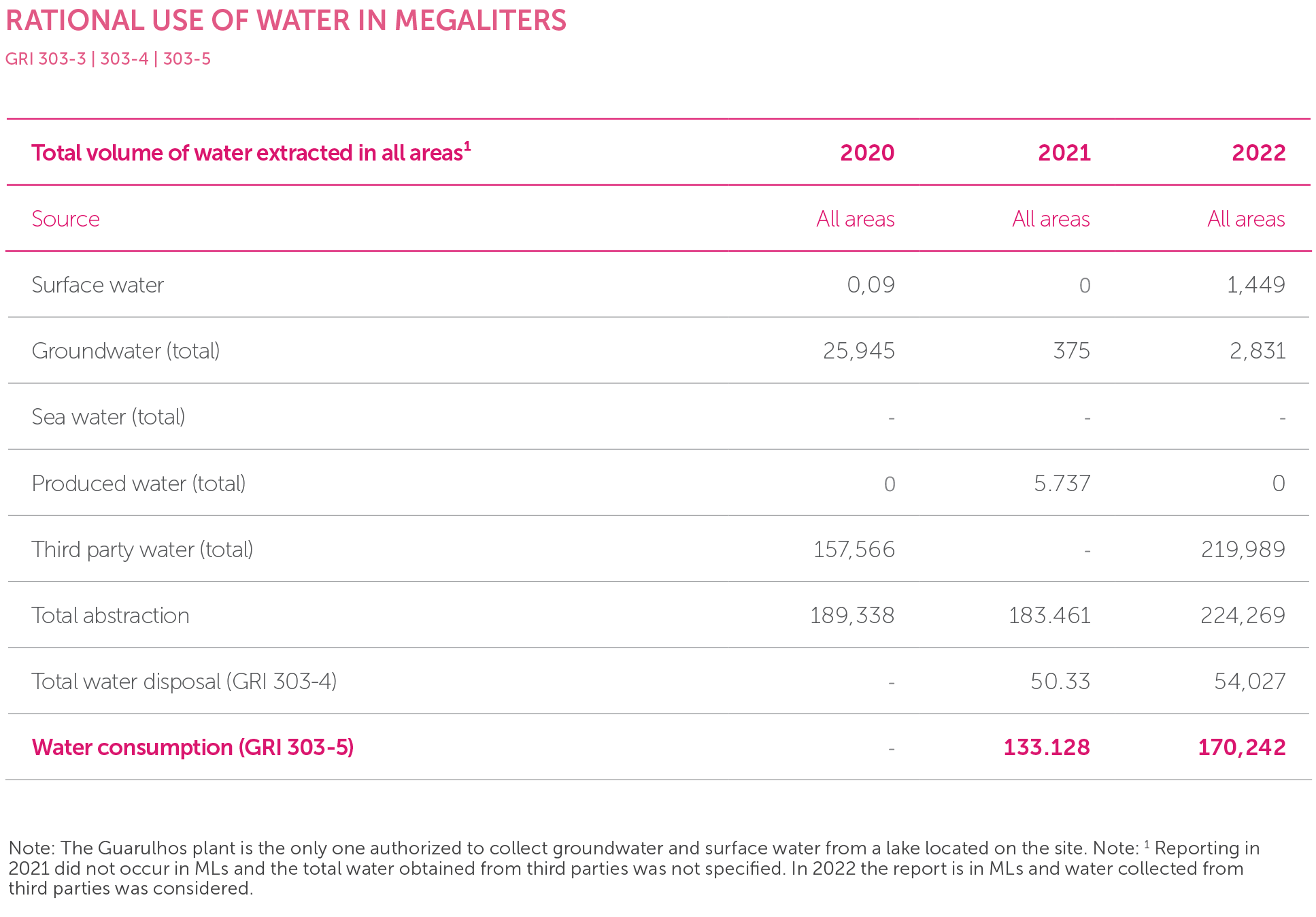

Water and Effluent Management

GRI 3-3 | 303-1 | 303-2 | 303-3 | 303-4 | 303-5

Water is supplied to Aché by a utility company, but we also have our own artesian wells from which we collect water for our production processes and for human consumption. Water consumption is monitored by way of indicators, which are based on the reading of hydrometers, invoices, spreadsheets and the monthly control of our building facilities, whose management is based on the IMS Policy.

The waste water generated in the production process is discarded in an Effluent Treatment Plant. We follow the principles and standards of disposal established in Decree No. 8,468/1976, of the State of São Paulo and in Conama Resolution No. 430. With regard to the profile of the water bodies that receive the treated effluent, in the Aché Guarulhos unit it is disposed of in the Cubas Stream and the Tietê River, while in all other plants the effluent is discharged into the sewage collection network.

The increase in water consumption in 2022 is a reflection of the increase in production, the start of pPhase II operations (manufacture of solids) at the Pernambuco unit and expansion of the production area (microdosing) in São Paulo.

WATER CONSUMPTION IN MEGALITERS

GRI 303-5

Note: Numerical data are in portuguese.